Cables, Wires and Accessories for the Food and Beverage Industry

The requirements for machines and their electrical components in the food processing industry go far beyond the standard of classical plant engineering. The topic of hygiene plays a key role here. Production plants and their components must have a “hygienic design”; cables and wires as well as cable accessories in the form of connectors and housings are not exempt from this.

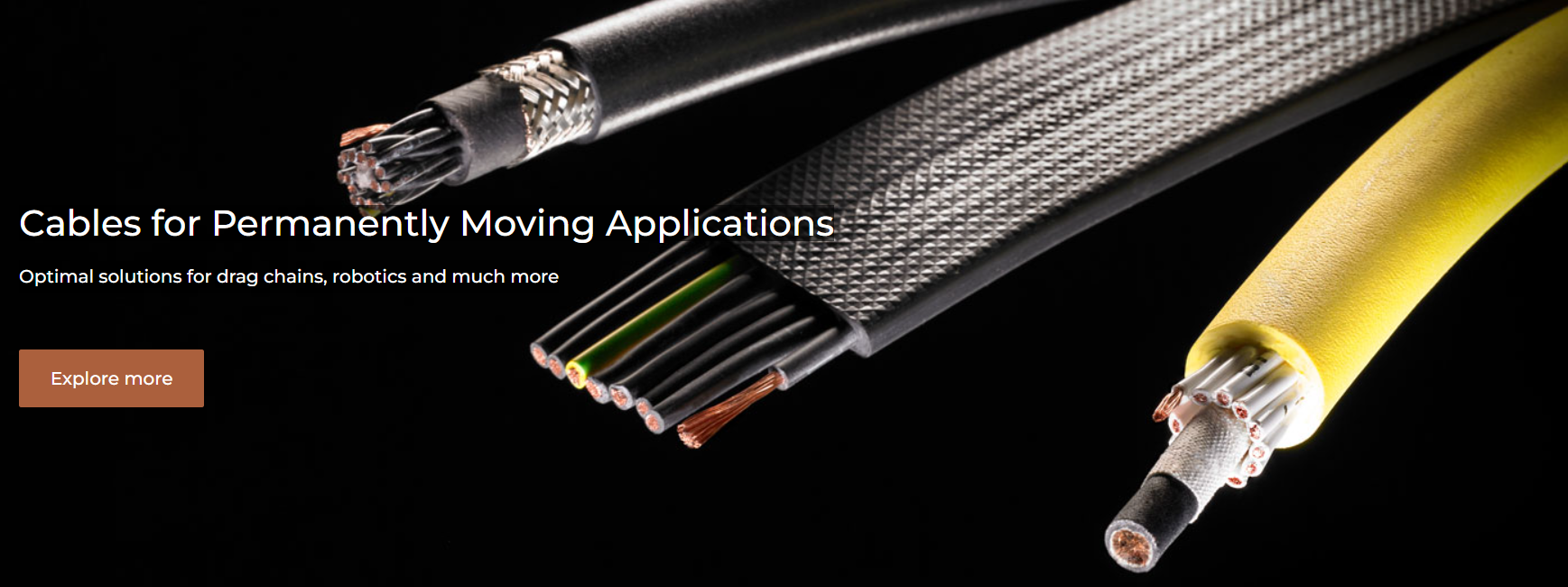

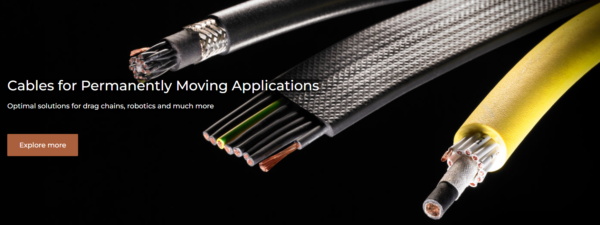

In the food and beverage industry, the primary goal is to prevent product contamination. A contribution to this is made by the hygienic design of production facilities and their components. In addition to the actual design, which must be constructed in such way that no harmful microorganisms can settle, the systems must also be easy to clean and be able to cope with aggressive cleaning and disinfecting agents as well as hot steam. HELUKABEL offers a wide range of control and power cables that are highly resistant to thermal, chemical and mechanical stress.

HELUKABEL also has the appropriate cable accessories in its portfolio: The HELUTOP HT-Clean for example, has a particularly smooth surface so that dirt of all kinds cannot stick to it. The stainless-steel screw connection is also resistant to all common chemical cleaning agents. It is approved by the EHEDG (European Hygienic Engineering & Design Group) and is therefore suitable for the safe production of food. In addition, the fitting complies with FDA (Food and Drug Administration) requirements and is Ecolab-certified.